Factors to Consider When Choosing a Material Before diving into...

Read More

Experience unmatched precision and quality with our custom CNC machined parts. Built to your exact specifications, we deliver excellence across India and the Middle East.

High-quality CNC machining doesn’t have to break the bank. We deliver precision parts that meet the highest standards, at competitive prices.

Whether it’s automotive, aerospace, or industrial applications, we craft precision parts tailored to your unique needs.

Machine Shop Turning & Milling

Crafting precision machined parts to fit your requirements with expertise. Our specialized manufacturing ensures accurate and tailored components. Trust us for precision, reliability, and exceptional craftsmanship.

What We Offer?

Automobile

Oil & Gas

Pumps & Motors

Textiles

Marine

Aerospace

Machinery & Equipements

Hydraulic & Pneumatic

Why Choose Us?

Custom Solutions for Every Industry

Teju Automation Prototype, a professional CNC machining manufacturer based in India, specializes in delivering swift CNC machining capabilities and advanced services to the global market.

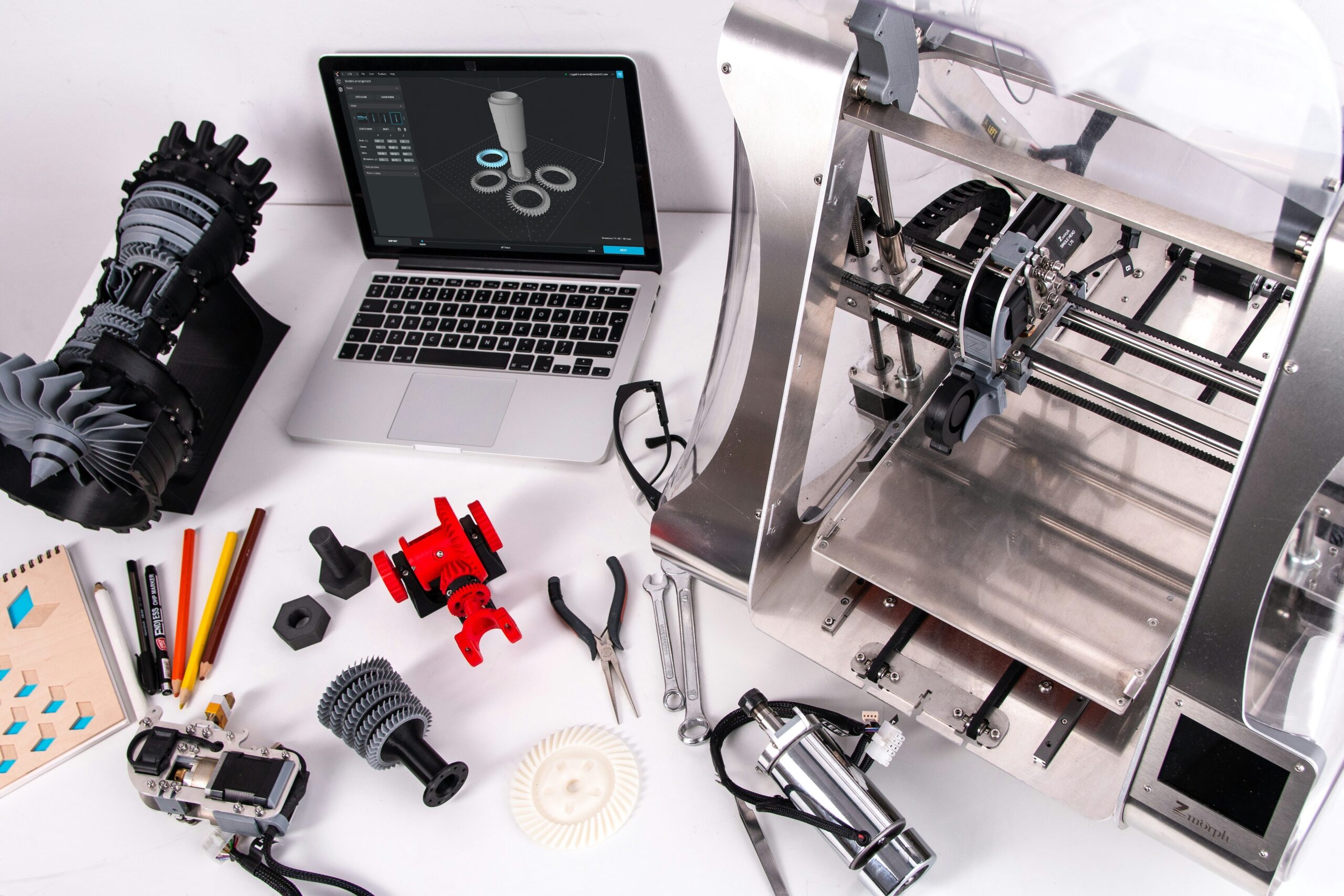

Our cutting-edge CNC machines are complemented by state-of-the-art software, enabling us to swiftly produce parts and components with exceptional precision. Whether it’s CNC prototyping or low-volume production.

Teju Automation offers competitive pricing without compromising on superior quality.

Our highly skilled staff and advanced equipment empower us to take on even the most intricate projects, as we thrive on embracing challenges.

6+ Years On The Market

Happy Customers Worldwide

99% Customer Satisfaction

Quality management

ISO Certified

Advanced Equipements

Precision Machined Parts, Built for Your Success

We are proud to be large enough to handle our customer needs yet small enough to offer the personal attention customer appreciate

Services for Transforming Prototypes into Products

Tailored Solutions for Your Distinctive Requirements: Extensive Manufacturing and Machining Expertise

Sheet Metal Fabrications

» Top-notch sheet metal fabrication service

» Latest technology and advanced machinery

» Various metals to fulfill diverse project requirements.

Support Service

We also do,

Heat Treatment, Plating, Blackening, Painting, Powder Coating, Chroming, Hydro Test, Surface Treatment, Grinding & etc..

Our Manufacturing Process

Send Drawings

Material Inspection

Programing

CNC Machining

Inspection

Packaging

Latest Updates

Here is every single update

Top 5 Trends Shaping the Future of Precision Machining

1. Automation and Smart Factories Automation is no longer a...

Read More